When upgrading an electrical system, many homeowners wonder whether copper or aluminum wiring is the better choice. Both metals are conductive and carry electricity efficiently, but their characteristics vary. In the 70s, builders often used aluminum wiring in house construction, making it a popular option of that era.

Now, more options are available, and understanding the difference helps in making an informed decision. The right wiring affects safety, efficiency, and long-term durability, so let’s dive in and explore the best solution for your home that ensures reliability.

What is Copper Wiring?

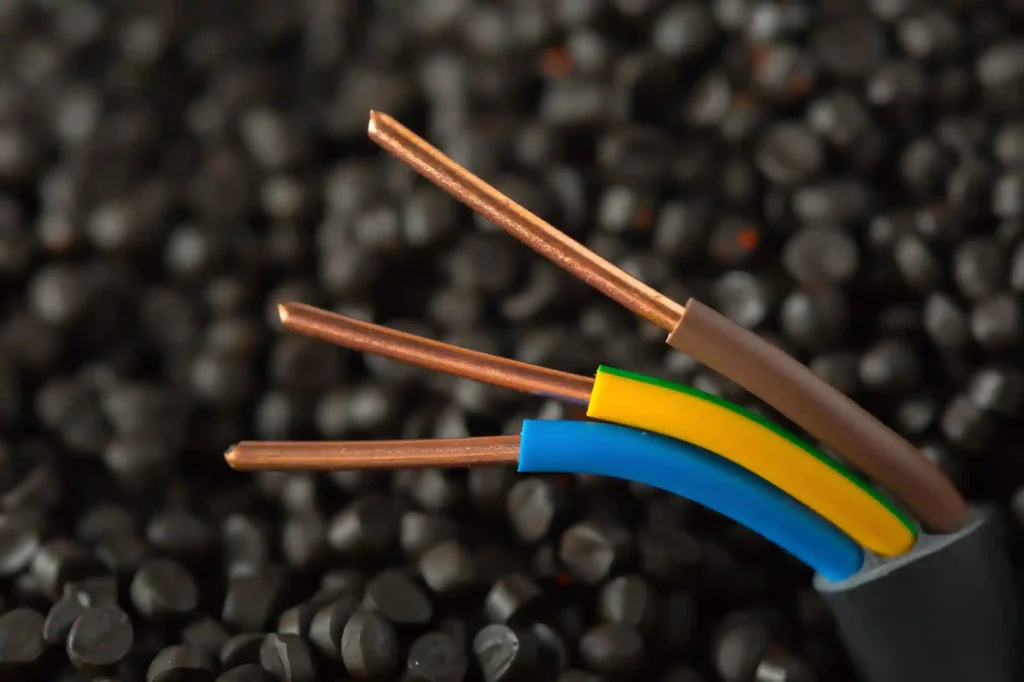

Copper wiring is made from copper, a strong and flexible metal used to carry electricity. It is commonly found in homes, offices, and industrial buildings. Copper is one of the best materials for electrical wiring because it is an excellent conductor, meaning electricity can flow through it easily.

Electricians and engineers prefer copper wiring because it is durable and does not rust or break easily. It can handle high amounts of electricity without overheating, making it a safe choice for wiring in homes. Copper wires are also easy to bend, which helps in installing them in different places.

In short, copper wiring is a reliable and long-lasting option for electrical systems. It ensures a steady flow of electricity and reduces the chances of fire hazards, making it a popular choice for wiring in many buildings.

What is Aluminum Wiring?

Aluminum wiring is made from aluminum, a lightweight metal that carries electricity. It was commonly used in homes and buildings, especially in the 1960s and 1970s, because it was cheaper than copper. Aluminum is a good conductor, meaning it allows electricity to pass through it easily.

However, aluminum wiring has some drawbacks. It expands and contracts more than copper when electricity flows through it. Over time, this movement can cause the wires to loosen, which may lead to overheating and increase the risk of electrical fires. That’s why electricians today often prefer copper wiring over aluminum for safety reasons.

Despite its challenges, aluminum wiring is still used in some electrical systems, especially for large power lines and appliances. When installed properly with the right connectors, it can work safely and efficiently.

Key Differences Between Copper vs Aluminum Wiring

When choosing between copper and aluminum wiring, it’s important to understand their fire hazards, electrical load handling, conductivity and efficiency, longevity, and cost. Each material has unique properties that impact safety, durability, and performance in a home’s electrical system.

Fire Hazards & Safety Comparison

| Category | ✅ Positive | ❌ Negative |

|---|---|---|

| Fire Hazards & Safety | Better thermal resistance, reduces fire hazards, less likely to overheat if installed correctly. | More prone to overheating, especially in homes from the 60s and 70s. Can cause loose connections, increasing fire risks. |

| Corrosion & Conductivity | Does not corrode easily, maintains strong conductivity over time. | Corrodes and forms an oxide layer, which increases resistance and lowers conductivity. |

| Electrical Load Handling | Has higher ampacity, carries higher loads without overheating, reliable for modern homes. | Expands when heated, leading to loose connections, especially in older homes with solid conductor wiring. |

| Efficiency & Performance | Used since the 19th century, offers higher efficiency and safe flow of electricity in residential applications. | More prone to overheating when load increases, may not perform well in homes designed for copper wiring. |

| Longevity & Durability | Excellent resistance to corrosion, does not fatigue easily, performs well under heavy load conditions. | Degrades faster, prone to brittleness and fatigue, especially when subjected to vibrations. |

| Maintenance & Inspections | Requires less frequent maintenance, remains reliable over the long term. | Needs frequent inspection due to higher susceptibility to damage and wear. |

| Cost & Affordability | Higher initial cost, but lower long-term maintenance makes it a better investment. | More cost-effective initially, but higher maintenance and repair costs over time. |

Which Wiring is Right for You?

Choosing between copper and aluminum wiring depends on your needs, budget, and safety concerns. Each type has its own strengths, so let’s break it down in a simple way.

If you want safety and durability, copper wiring is the better choice. It lasts longer, doesn’t loosen over time, and reduces the risk of electrical fires. That’s why most electricians recommend copper for homes and buildings.

If you are on a tight budget and need wiring for large projects like power lines or industrial settings, aluminum wiring may be a more affordable option. However, it requires careful installation and regular maintenance to prevent risks.

Best Choice for Different Needs:

For homes and small buildings: Copper wiring is safer and lasts longer.

For large power lines and industries: Aluminum wiring is more cost-effective and easier to install.

For budget-friendly projects: Aluminum wiring can work, but it needs proper maintenance.

Final Verdict

If safety and long-term reliability are your priority, go with copper wiring. If you need a cost-effective solution for a big project, aluminum wiring might work, but it requires extra care. Always consult an electrician to make the best choice for your specific needs!

For professional electrical services, visit Spark Edge Electric and let our experts help you with safe and reliable wiring solutions.